How food-grade HDPE plastic boxes ensure hygienic storage

According to UK Research and Innovation, there are an estimated 2.4 million cases of foodborne illnesses, such as food poisoning, in the UK. The cause of illness is often a microbial pathogen passed over to the food from the environment, livestock or people. This equates to an annual cost of £9 billion in illnesses, with £6 billion from unknown causes.

With such high risk of food contamination leading to illness, ensuring food is properly handled and stored from farm to plate is essential in risk management and food safety and hygiene.

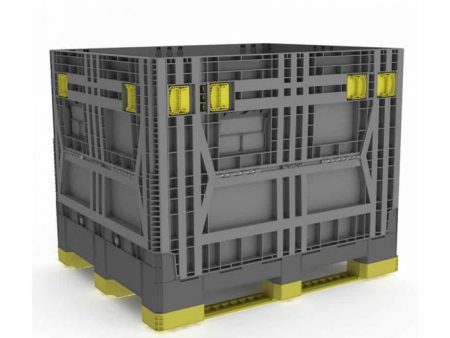

Our food-grade high-density polyethylene (HDPE) plastic boxes are a popular choice amongst those in the food industry because of their unique properties that lend themselves to an environment that requires the highest standards of cleanliness.

Why is food safety important?

Food safety ensures that all consumable goods are free from contamination and are handled and stored in ways that minimise the risk of foodborne illnesses. Ensuring food safety preserves nutritional content, extends shelf life and, most importantly, protects public health.

In a nutshell, following correct food safety guidelines helps:

- Prevent foodborne illnesses and contamination. These can lead to severe health issues such as food poisoning and infection. Following food safety guidelines minimises the risk of bacterial growth and contamination from harmful chemicals and pathogens.

- Maintain nutritional value. Storing food correctly preserves their nutritional value as exposure to specific environmental factors such as light, air and temperature can degrade vitamins and mineral content, in turn degrading their quality.

- Helps with the prevention of food waste. It is thought that a third of all food produced globally will go to waste, and in the UK alone, we throw away 9.5 million tonnes of food waste per year. By ensuring that food is handled properly during processing, storage and transport, you can help in improving this huge statistic and prevent perfectly good food from going to landfills.

- Consumer confidence. Everyone likes to know their food has been handled diligently and carefully, with respect for the end consumer. This builds trust between the consumers and retailers which encourages repeat purchases and customer loyalty.

There are also great economic benefits to storing your food in high-quality food-grade storage containers. With correct care and storage, you’re likely to induce less waste and financial losses through spoiled food.

And arguably above all, there are food safety regulations that must be followed to protect public health and avoid legal repercussions.

UK food safety frameworks

In the UK, food handling certifications, licensing, and regulations are governed by several key frameworks. Those that work with food in any capacity need to adhere to these frameworks and train in the relevant courses in order to ensure public health and safety.

Food safety certification begins with basic training through a Level 1 Food Safety/Hygiene Certificate, progressing to more comprehensive training at Levels 2 and 3 for those in supervisory roles. These courses ensure that food handlers are well-equipped to maintain high standards of hygiene and safety.

Food businesses must navigate specific licensing requirements, starting with registration with local authorities at least 28 days before commencing operations. Certain businesses, especially those dealing with high-risk products like meat and dairy, need additional approvals.

Compliance with food safety regulations is monitored through inspections by Environmental Health Officers (EHOs) and the Food Hygiene Rating Scheme (FHRS). These measures, overseen by the Food Standards Agency (FSA), aim to uphold hygiene standards and provide transparency for consumers.

All of our food-grade boxes are compliant with these strict frameworks and help maintain the high levels of standards needed when working in the food industry.

How can food-grade HDPE plastic boxes help?

Our food-grade HDPE plastic boxes are widely used in the food industry for their hygienic properties which perfectly lend themselves to food storage and transportation, helping perishables remain fresh and safe.

- Non-toxic material: Our food-grade storage boxes are made from non-toxic material, meaning it does not leach harmful chemicals and plastics into the food, making our HDPE plastic boxes perfect for storing both dry and wet products.

- Resistant to external factors: HDPE is highly resistant to moisture, chemicals and solvents and acts as a strong barrier against airborne contamination and pests. This is a huge factor when it comes to keeping food safe for human consumption, fresh and maintaining its quality.

- Durable storage: HDPE plastic is strong and durable. This not only ensures you’re investing in quality products, but also means your food items remain fresh and safe – even with regular, rigorous usage.

- Temperature tolerance: Our HDPE plastic boxes are made to withstand a range of temperatures, making them ideal for storing food in industrial fridges and freezers without compromising the boxes’ protective qualities.

- Easy to clean: Arguably one of the most important factors! Food-grade plastic boxes need to be easy to clean and sanitise for reuse without risk of contamination. Our food storage boxes won’t falter to high temperatures or industrial cleaning chemicals, allowing you to effectively remove food waste and bacteria after use.

All of these properties create a reliable, robust HDPE food storage box that keeps your food free from hazardous contaminants whilst preserving the quality and condition of your perishables.

Our food-grade HDPE storage boxes come in a variety of bold colours and capacity volumes, suitable for applications across a range of food suppliers and needs. Our industrial food storage boxes are moulded with 3-runners for easy transportation of goods from warehouse to warehouse and beyond; they are even compatible with handling machinery allowing you to efficiently speed up your logistics processes. They also feature grippable bases, ensuring your goods remain secure when in transit between pallets and places.

Why choose HDPE for food storage?

Rebox Storage offers both high-density polyethylene and medium-density polyethylene storage boxes, both of which are suitable for food storage however each has different features and benefits.

High-density polyethylene (HDPE) has a density range of 0.941 to 0.965 g/cm³ and a linear structure with minimal branching, resulting in tightly packed molecules. This creates a box that is chosen for its strength and rigidity, making it suitable for applications that call for durability.

Medium-density polyethylene (MDPE) however has a a density range of 0.926 to 0.940 g/cm³ and more branching than HDPE, leading to a slightly less dense molecular arrangement. This creates a box that is more flexible without compromising on strength.

And although both materials boast great chemical resistance, HDPE takes the edge over MDPE in resisting certain chemicals due to its higher density.

HDPE is also the standard material for many food storage items, including milk jugs, water bottles and food storage containers, indicating its widespread acceptance and reliability in the food industry.

Whilst MDPE has its own set of advantages, HDPE provides superior strength, chemical resistance and all-important ease of cleaning needed when it comes to storing food items. These properties ensure that food remains safe, uncontaminated and is preserved for longer periods of time, making HDPE the optimal material for food-grade containers.

Which food industries should use food-grade storage boxes?

All food-related industries should be using food-grade materials when it comes to producing, storing, organising and transporting food goods. Fisheries and bakeries, for example, benefit greatly from food-safe HDPE storage boxes due to their durability, hygienic properties and versatility.

HDPE is resistant to moisture and chemicals, making it ideal for the cold and wet environments of fisheries. However, due to their moisture and temperature resistance, they’re also ideal for keeping bakery ingredients and products dry.

Fishing fleets will specifically benefit from food-safe storage such as Saeplast containers due to their incredible temperature control, which is perfect for preserving the freshness of fish from sea to plate. You can learn more about our Saeplast insulated containers here.

Why choose Rebox Storage?

Not only are we an independent stockist of plastic storage solutions, offering a wide range of high-quality products including boxes, pallets, and more, but we also have unbeatable customer support and next-day delivery service.

Being a plastic storage retailer, we take our environmental impact seriously. Our boxes are made using recycled plastic and are also completely recyclable, making our products closed-loop recycled. All of our products are available in various sizes, colours and configurations to meet diverse needs across industries like food, healthcare, and retail.

With over 30 years of experience, Rebox Storage provides expert advice to help customers choose the most effective storage solutions.